I’ve been listening to the second edition of “Lean Thinking”, released in audio format on CD. It helps burn the miles commuting in California. My kids listened to about 30 seconds before declaring the speaker monotone and boring. Yes, well.. it’s the content not the presentation, right? On the last of4 disks, Track #5, there’s a section on right-sizing the tool base. If this term doesn’t mean anything to you, you’ll have to do some Lean Thinking research before understanding where I’m going.

As I listened, all of a sudden, a thought hit me. This is the heart of the issue between Linux tool-chain mentality and Microsoft super-app mentality. “Two little, customized, bare bones tool machines may be cheaper and fit better into the product flow process than one big monster with all the bells and whistles with stupendous burst throughput rates.” The authors of the book are bound up in producing physical items, straining to apply their ideas outside this realm. It’s what they know. But it hadn’t been clear how any of this applies to my world of technical consulting, intellectual property, management decisions, computer technology, entrepreneurial dexterity, and billable hours.

Then, Microsoft Word popped into my head, combined with Adobe Acrobat to create pdfs. It’s something I do often for reasons of standardization and traceability, mostly. Both apps are fully capable, but do not adapt easily, have huge footprints, and large acquisition costs. This represents the classic “statue” tooling, machining, or assembly device left behind by a company as they move toward Lean Manufacturing.

In comparison, I’ve increasingly dumped files to the native PostScript format so prevalent in the UNIX world and high-end printers. When I need a pdf, I use the small Linux utility called ps2pdf13 to do so. This is my tiny tool chain. I know other Unix gurus are much better than me building tool chains, particularly if they can script things quickly. I’ve dabbled in this area handling graphic files — cropping, clipping, and aggregating. Yes, I use GIMP, but it’s easier to do batch conversions and distribution using command line utilities. Tool chains convert easy, are adaptable, easily upgraded. All those things the Lean Thinking manufacturing mentality is saying about manufacturing tools.

Someone recently asked me what Microsoft .NET was. And that’s hard to answer. It’s become such a big pervasive beast, it basically can become whatever you want it to become. “Lean” is not a word that comes to mind.

In my parallel world of a la carte, tool-chain software, it’s become more valuable to me to learn many net tools and compare, contrast, and recommend combinations that are correct and right-sized. Static web pages. Dynamic web pages. RSS. Blogs. Wikis. Databases. And many variants within each category. To design with tool-chains, it forces real questions as to the driving requirements. Not just an observation that some monster-app is cool, and how to shoe-horn our life or business into it. But rather what do we do in our business, and what’s the answer to deliver value to customers.

At work, another IT “big machine” came on line doing so much more than it needs to, and is casting a useless shadow of waste — not measurable waste in it’s metric, but measurable waste that is distributed into the organization infrastructure and hidden from normal accounting.

We’re converting to encrypted ID cards and passwords to log onto computers. A slight inconvenience, but that’s a known trade-off. The idea is that email and other traffic would be encrypted enroute across possibly public networks. And here, the first chink in the plan appeared in my mind when I heard of it a year ago. If that’s the goal, why are we levying a huge burden on each desktop, each desktop user, and each help technician? It’s the traditional formal monster process that has to be worked around at each work cell in a manufacturing plant.

Once all the install process and program has cranked through it’s paces (including lots of meetings, approvals, coordination briefs and memos), the issues have just begun. It turns out that any email handled by an old ID card is not readable by a new ID card (which must be done every so often). And so, we staff up another person or two to research ways around this, handle all the problem tickets, educate the workforce, and draw up instructions of how to install another band-aid, which, magically de-encrypts all the emails and end user can’t decrypt. Well, that’s true if the old encryption certificate is still available. And so it goes.

One IT manager even explained the new system was good because it handled encryption in transit and automatically left emails encrypted on the user account. And I wondered if anybody ever asked for this! The closest analogy I could think of is to ponder who would ever ask to keep an https: web page copy encrypted on their hard drive. Surely, this is an absurd shadow of waste creating a new requirement that doesn’t exist to justify its existence. Sheeesh…

Lean Thinking uses the phrase “value to the customer” incessantly. Very little else functions as the guiding light. So, what is the value to an IT customer? It has nothing to do with operating the computer in a new or fancy way. A relative was the first one to coin a phrase in my presence and I think he’s right. Computers (and IT services by extension) only in as much as it helps me do something I was doing without the computer.

All the time I spend doing software configuration, or backups, or installations, or network maintenance, etc are all total non-value adders. If all this was necessary to create a slide show brief to ask for funding for a new engineering project, I have to compare the “computer method” against a hand typed white paper, overhead hand-drawn slides.

Old fashioned, you say? When was the last time you did a zero-based audit of how much time your organization spends in a meeting coordinating the decisions to get the IT product or support to train people to know how to use the software package that will help them do the brief to get the money?

What if people and resources were simply and directly used to get the funding? Maybe a better researched proposal. Maybe a more convincing argument. Maybe powerful case studies. That’s lean thinking in my world.

Recommendation:

- IT Staff of large organization should look at tool chains rather than monster-apps.

- Zero-base audit the value chain to the customer for IT projects.

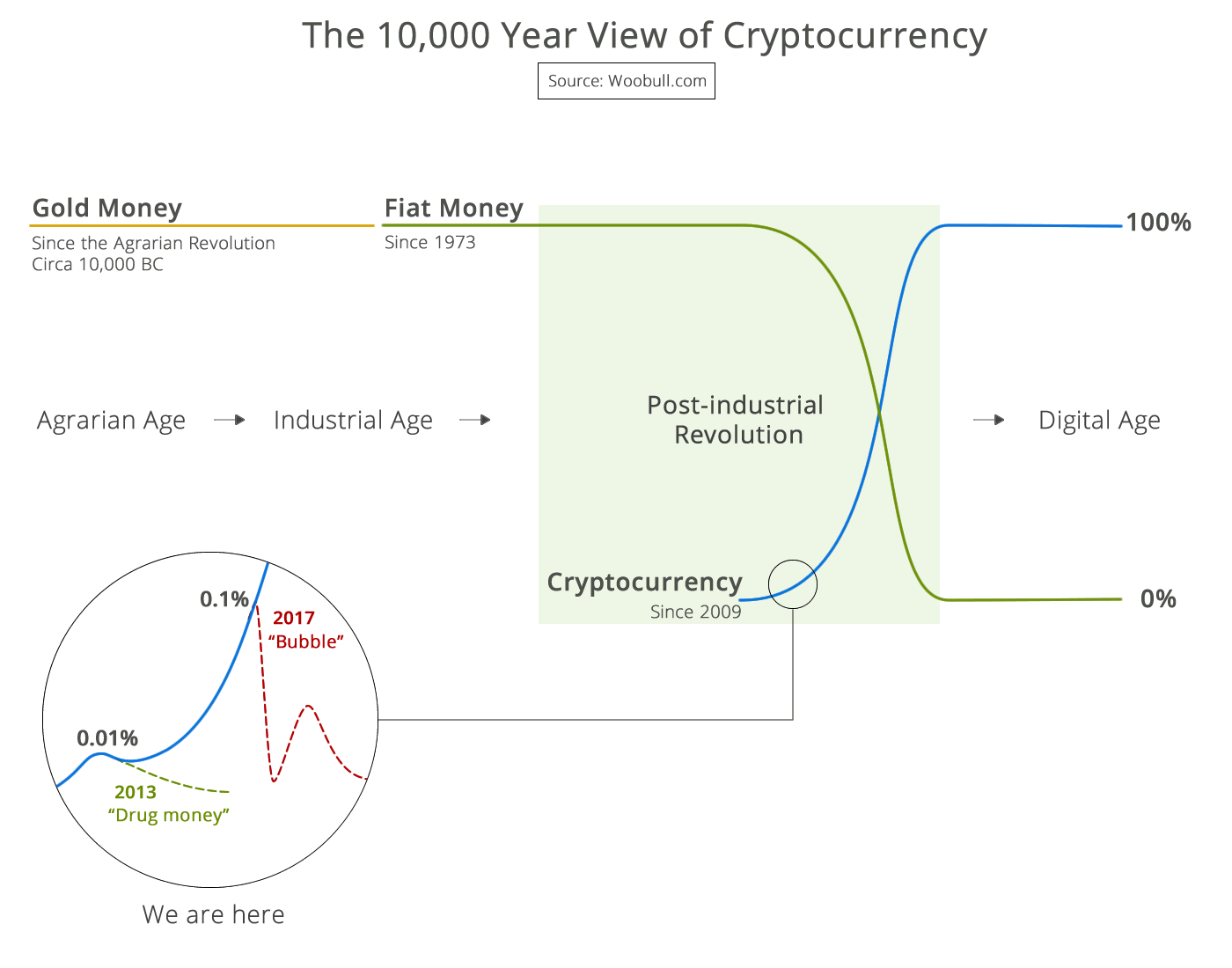

99% of ICOs Will Fail

99% of ICOs Will Fail The 10,000 year view of cryptocurrency

The 10,000 year view of cryptocurrency